Surface Sensing

Using my Human 2.0 Project as a jumping off point I started wondering about coordinate pressure sensing on a larger scale. Rather than having an area rug, I wanted the entire floor to be able to sense what was happening on top of it. As a colleague put it "The monitoring camera is the floor". The only trouble with having floor-sized sensors was the cost and scalability. An affordable solution had to be on the order of ~$1000 for a decently sized floor area (20ftx20ft). The resolution had to be small enough that at the very least individual footsteps could be picked out. I spent most of the Summer 2014 designing and prototyping different pressure sensor configurations. The goal was to reduce cost and have a solution that was modular.

Initial Prototypes Media

Version 1.0

After much testing and many prototypes, I was made aware of a company called Elsi Technologies from Finland. They had developed a sensing floor to monitor the elderly in nursing homes. They used capacitive sensing over pressure, but what really appealed to me was their configuration. Rather than trying to make a tile, they made strips. So rather than having a sensor with 25 nodes arranged 5x5, you have just one long strip of 1x25. The mat is 9' x 4' and contains 96 sensing points. The resolution is about 6"x6" so the system can capture unique footsteps. Cost of parts including the Arduino was $200. This means that for about $3500 the entire CityHome floor can be made into a sensing surface. While that amount may seem high, the cost reduces with bulk. Components are also cheeper than the integrated boards that are sold i.e. an Arduino chip costs far less than the Arduino UNO.

Applications Of This System:

Imagine if your floor was a giant touch screen. Imagine all of the data and interactions that could be created. Video games, entertainment, healthcare, are just some of the areas that could be revolutionized by inexpensive, pervasive floor-based sensing. I wan't the floor to be a part of the internet of things. Not just a surface, but one of the largest data collection tools in the proverbial arsenal. I have programmed some sample applications and linked videos below.

Within an ecosystem such as the CityHome where elements move and transform, the floor, walls, or even ceiling can serve as the sentinel. Anything that goes on within the space that touches either of those surfaces is tracked. These smart surfaces can then feedback into the intelligence of the system, to inform the transformation or learning algorithms governing the customizability of the space.

Version 1.0 Media

Adding projection to the floor could generate new forms of interaction and application design for the home. In this video the projector is overlaying the realtime raw data from Processing onto the mat.

Sample outputs from the data. Including threshold detection, trajectory mapping, and heat maps of frequently visited areas.

Version 2.0

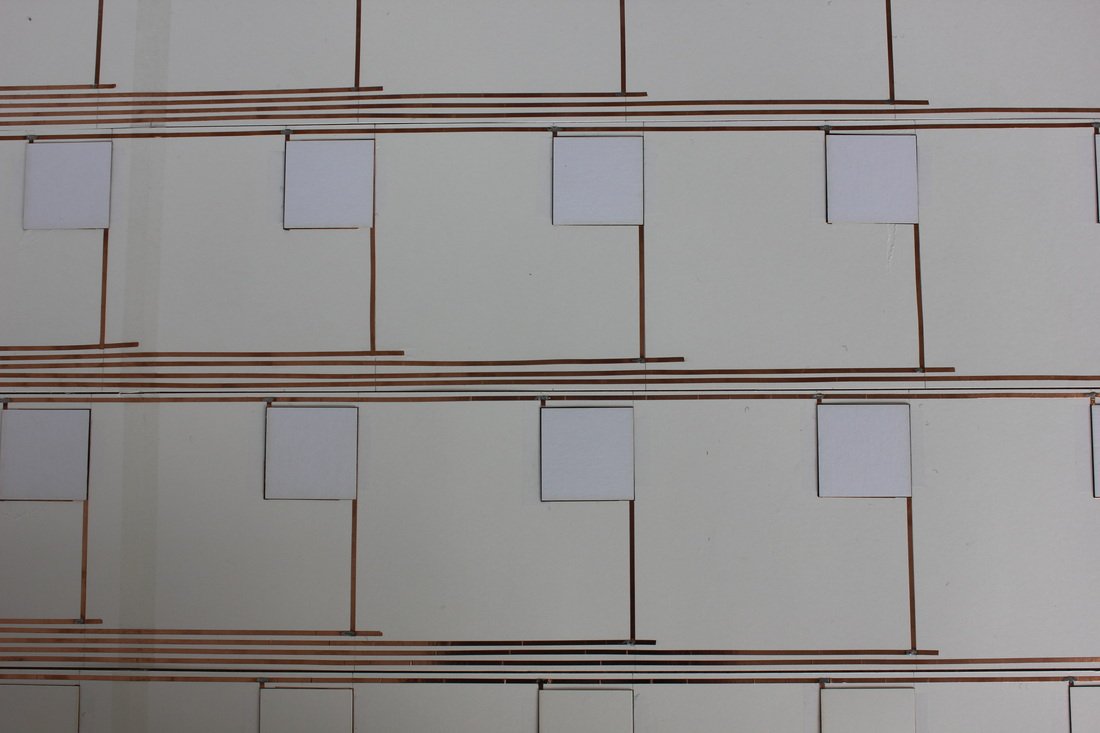

Now that I had tested a system using copper tape and off the shelf components, I wanted to design my own sensing surface and PCB for manufacturing. The sensing surface was designed as a bitmap image and inkjet printed on a substrate in a single pass. The ribbon connector cable was printed directly onto the sheet, removing a need for separate connector cables.

I first created a square grid of sensing surfaces which plugged into the circuitry from the first prototype. You can see it working with the Velostat material and visualization below.

Version 2.0 Media

Triangular Sensing Sheet

The square grid of sensors was good, but another colleague pointed out that by having overlapping triangular sensors, I could capture more area and be able to gauge relative position in the horizontal, due to differential pressure patterns on adjacent sensors.

PCB Design

In order to accommodate more sensors and fit within a smaller footprint I designed and fabricated a PCB using Altium Designer. I came up with the schematics myself, and enlisted the help of a student in Romania to layout the board. The final result was a PCB with 512 sensing inputs, 32 Multiplexers, 8 Shift Registers, and an Atmega microcontroller.

Though the signal is a bit noisy, I am able to read position and relative pressure on the PCB/Triangular Sensor Prototype